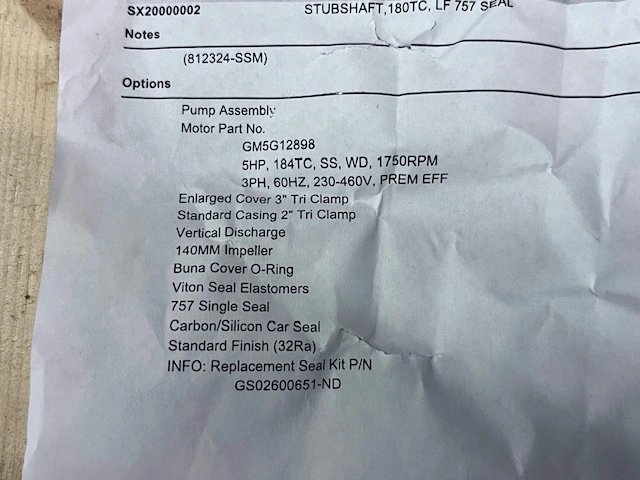

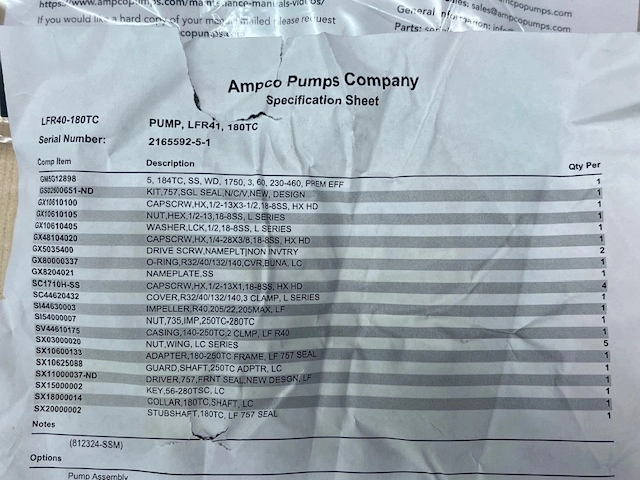

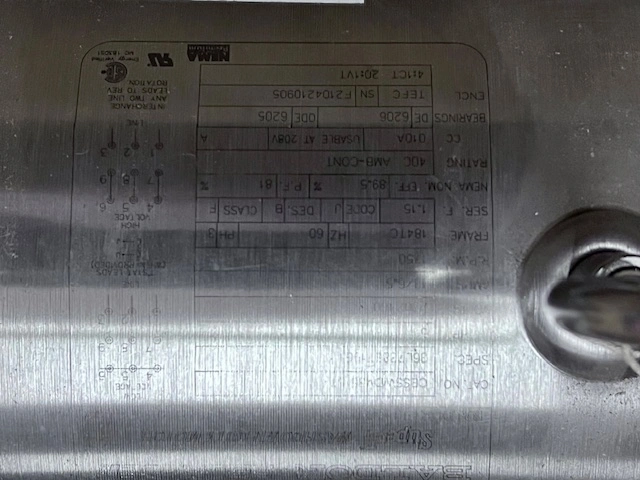

Ampco LF Series Centrifugal Pump LFR40-180TC

Product ID: P13816

- Manufacture: Ampco

- Serial Number: 2165592-5-1

- Motor 5HP, 184TC, SS, WD, 1750 RPM, 230-460V

New Storeroom Spare Ampco 5HP Centrifugal Pump

Request A Quote

Related Products

- Masterflex I/P series peristaltic pumps have powerful motors and better protection from industry hazards. Ideal for manufacturing, process and industrial applications.

- manufacture

- Material: CF8M

- Condition: New Surplus

- manufacture

- New Surplus

- Material CF8M

- manufacture

- Manufacture: Vickers Hydrokraft

- Part Number: MF500M8M

- Condition: Rebuilt to new

- Made in Germany

- Manufacture: Goulds

- Model: 3175

- Size: 3×6-12

- Manufacture: Worthington

- Model: D1011

- Size: 3×4-8

- Manufacture: IMO

- Part Number: 82160/62080RIP088

- Condition: Rebuilt

- Manufacture: Sulzer / Bingham

- Model: MSD-D

- Size: 4x8x10.5C

- 1400 gpm

- 2000 ft HD

- 3560 rpm

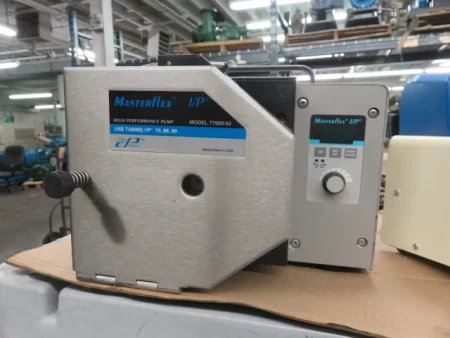

Cole-Parmer Masterflex I/P Series Peristaltic Pump , Powerful Systems

X

Cole-Parmer Masterflex I/P Series Peristaltic Pump , Powerful Systems

Product ID: T11335

Product id: T11335

Description: Masterflex I/P series peristaltic pumps have powerful motors and better..Goulds Impeller Part No. 5620?

X

Goulds Impeller Part No. 5620?

Product ID: P 7086

Product id: P 7086

Description: Material: CF8MCondition: New SurplusmanufactureUpper and Lower Casing equal Goulds pump model 3405 size 10x12x17

X

Upper and Lower Casing equal Goulds pump model 3405 size 10x12x17

Product ID: PT5415

Product id: PT5415

Description: New SurplusMaterial CF8M manufactureVickers Hydrokraft Hydraulic Pump MF500M8M

X

Vickers Hydrokraft Hydraulic Pump MF500M8M

Product ID: PT7023

Product id: PT7023

Description: Manufacture: Vickers HydrokraftPart Number: MF500M8MCondition: Rebuilt to newMade in GermanyGoulds model 3175 Stock Pump size 3×6-12 material 316ss

X

Goulds model 3175 Stock Pump size 3×6-12 material 316ss

Product ID: PM11631

Product id: PM11631

Description: Manufacture: GouldsModel: 3175Size: 3x6-12Worthington Pump Model D1011 size 3×4-8

X

Worthington Pump Model D1011 size 3×4-8

Product ID: PT11608

Product id: PT11608

Description: Manufacture: WorthingtonModel: D1011Size: 3x4-8IMO Hydraulic Pump Number 82160/62080RIP088

X

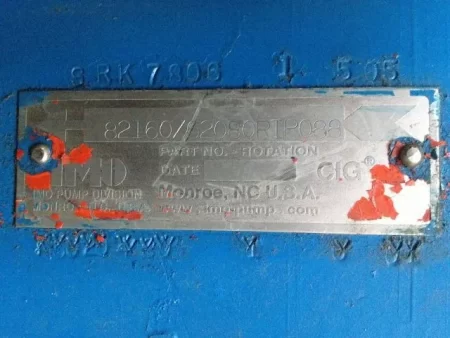

IMO Hydraulic Pump Number 82160/62080RIP088

Product ID: PT 7022

Product id: PT 7022

Description: Manufacture: IMOPart Number: 82160/62080RIP088Condition: RebuiltSulzer / Bingham MSD-D 5 Stages 4x8x10.5C Pump

X

Sulzer / Bingham MSD-D 5 Stages 4x8x10.5C Pump

Product ID: PT6268

Product id: PT6268

Description: Manufacture: Sulzer / BinghamModel: MSD-DSize: 4x8x10.5C1400 gpm2000 ft HD3560 rpm